When it comes to inventory management and supply chain management, success begins with raw data and expands from there. Retailers look to implement a variety of product identifiers. The raw data structure has to begin with either a Stock Keeping Unit or a Universal Product Code. Most associates such as business owners, operations managers, and supply chain directors understand the relevance of both, and each has particular impacts on how one tracks inventory levels, processes sales, and how one’s business integrates with the marketplace.

Operational constraints, such as a missing warehouse pick or a lag at the register, both stem from the misconception of how these codes work. When a business is growing and consolidating datasets, it is a common mistake to assume these codes can be used interchangeably. It is a common misconception that closes the doors on many growing opportunities. This document will outline how both SKUs and UPCs can be used to maximum efficiency and to eliminate operational bottlenecks.

What is a Stock Keeping Unit (SKU)?

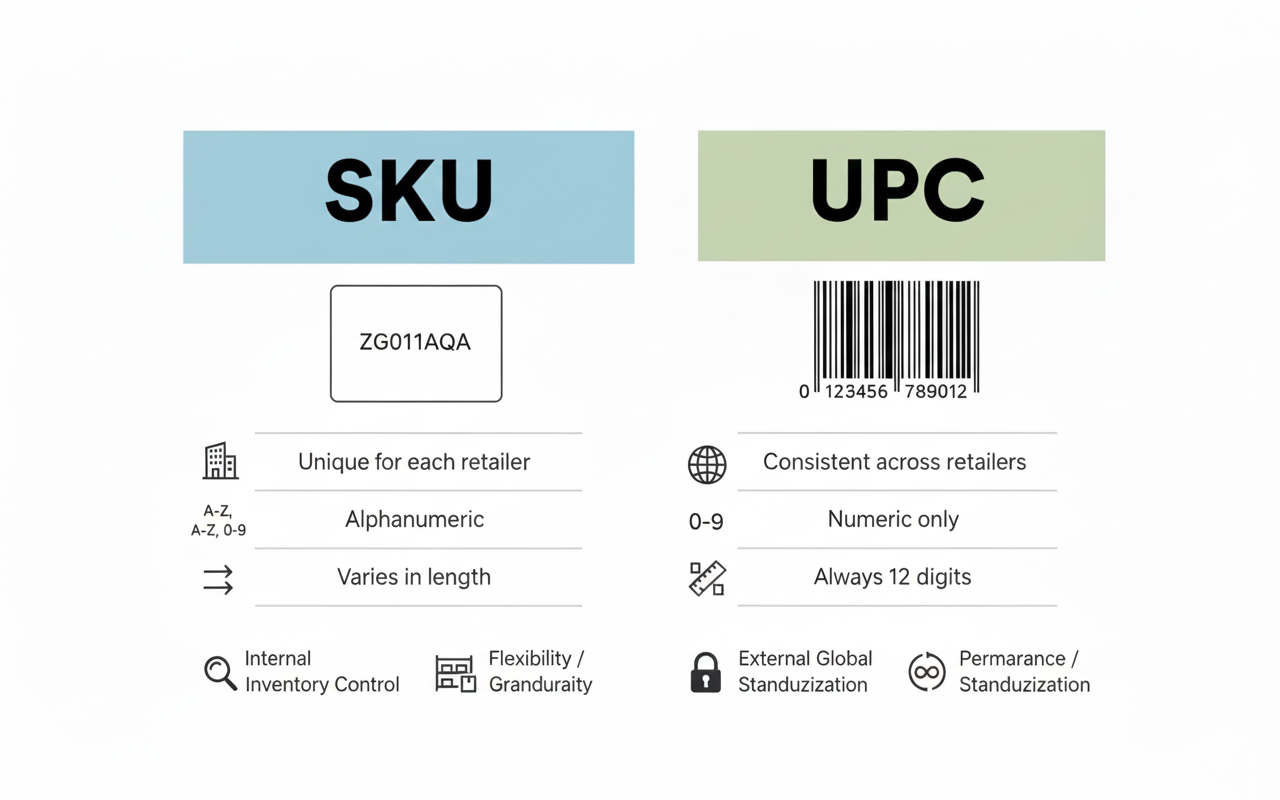

In the world of retail, a stock-keeping unit is the most basic level of an inventory management system. Unlike a global product code, an SKU is an alphanumeric code that a business has to create in order to keep track of stock levels and sales.

Its primary purpose is to answer the question: “What do we have, and where is it?“ Because it is completely customizable and free to create, an own SKU system makes it possible to do detailed internal use tracking. When a SKU is well made, it allows warehouse workers to determine without scanning the SKU code what brand, style, color, and size the item is by using a combination of letters and numbers that make it easily “readable” by humans to determine this. This allows firms to adjust the logic to their particular reporting requirements, tracking everything from physical products to services that are not.

What is a Universal Product Code (UPC)?

The UPC code is the external use retail standard, and is governed by the global standards organization GS1. This is a 12-digit number—often referred to as a UPC barcode— that is solely numeric and that enables the entire world’s supply chain to identify a product uniquely and without variation. It is important to note that the UPC is a subset of the broader Global Trade Item Number (GTIN) family. While Europe utilizes the 13-digit EAN (European Article Number), the 12-digit UPC remains the dominant format in North America. Despite these regional differences, modern scanners are universally capable of reading both, ensuring cross-border commerce remains seamless.

What makes UPCs special is that they are both universal and permanent. When a product number is first bought and registered to a product, that identification number is uniform, no matter where the item is sold, e.g., a local store or a big multinational store. It links a tangible item to a unique digital identity, so that point of sale (POS) scanners anywhere globally can access the correct price and product description within seconds. UPC codes are different from SKUs in that they cannot just be made up, but must be licensed to ensure that no two products in the world have the same code.

The Vital Role of Identifiers in Business Operations

It is a gross understatement to say that the SKU vs. UPC distinction results in just stickers on a box. In a high-volume retail or industrial setting, these identifiers act as the control system for the entire operation. They create a high degree of digital precision by transmuting physically tracked objects into data, a task that is infeasible if done by manual descriptions. This data transformation is the catalyst for automation. Without consistent identifiers, modern advancements like robotic process automation (RPA) in warehouses or automated conveyor sortation systems would be impossible to implement.

- Reducing Human Error

Without any precise product identification, inventory management processes can boil down to descriptions. “Small blue widget” can mean vastly different things when an employee’s “blue” can be someone else’s “teal.” This is where having specific descriptors prevents ambiguity. Furthermore, cultural and linguistic barriers in global supply chains exacerbate this issue. A description in English may be misinterpreted by a packer in a different country, but a barcode is a universal language that transcends translation errors. Scanning a code is binary: it is either the right item, or it is not. This system serves to be important for keeping the inventory balanced, especially for e-commerce, where picking and shipping errors create expensive returns and punish the business with a negative reputation.

- Accelerating Replenishment Speed

Supply chains run on speed. The instant a product is sold, that data point must trigger a reaction. Identifiers make it possible to set automated reordering points. If there is a low count of an SKU number at a certain point, it can trigger the system to auto-generate a purchase order. This concept is central to “Just-in-Time” (JIT) inventory strategies. By trusting the data generated by SKU scans, businesses can reduce the amount of capital tied up in safety stock, knowing that their reorder triggers are based on accurate, real-time consumption data rather than guesswork. This is important because without automated code systems, buyers would have to walk the floor to count stock, an extremely slow process for today’s commerce.

- Enabling Data Analysis and Forecasting

Identifiers grant access to business intelligence regarding product performance. Product tracking sales at the SKU level allows businesses to spot patterns that aggregated data might overlook. You may know that “T-shirts” are selling well; however, SKU analysis may show that “Graphic Tees in Size XL” are selling, while “Plain Tees in Size S” are selling at a standstill. This helps businesses have a clear direction in spending by selling the high-moving styles and stepping out of the slower-moving stock.

UPC vs SKU: Core Differences and Functional Comparison

Achieving operational excellence gained through live interaction comes after the technical definitions and key differences have been understood. It is helpful to visualize the relationship as a hierarchy: the UPC is the global constant, while the SKU is the local variable. The UPC bridges the manufacturer to the retailer, while the SKU bridges the warehouse to the accountant.

Internal Inventory Control vs. External Global Standardization

The primary difference is in the target audience that the item is designed for and the area of application.

The SKU answers: “What is in my warehouse?” It has an introspective viewpoint. It is concerned with warehouse operations and the logistics of the COGS and vendor relations specific to your company. It facilitates the calculation of turnover rates and holding costs, metrics that are internal to the financial health of the business and irrelevant to the consumer.

- Flexibility: An SKU is a living asset in your system. If your supplier changes, your warehouse is reorganized, or your inventory management software is updated, it is up to you to decide how to structure your SKU. It is entirely under your control.

- Granularity: For SKUs, the condition of the item is something that they can track. For instance, even though both products have the same UPC, there can be one SKU for a New iPhone and another for a refurbished iPhone.

The UPC answers: “What is this product in the market?” It is looking outside from the company perspective, focusing on compliance, listing the retail products in the marketplace, and the transactions made by customers.

- Permanence: One of the main characteristics of a UPC is that it is immutable. For a product, once a UPC is assigned, it is with that same individual product for the entire lifetime of that product. You cannot change a product’s UPC because you changed the internal warehousing strategy.

- Normalización: The UPC does not care about your internal logic. It does not care where you keep the item, the storage location of the item, or the profit you make on it. The UPC just verifies the global identity of that item. This standardization is also what allows for competitive price-matching apps and comparison shopping engines to function. They rely on the UPC to ensure they are comparing the exact same product across different retailers.

| Característica | SKU (Stock Keeping Unit) | UPC (Universal Product Code) |

| Primary Purpose | Internal use tracking and warehouse management. | External use identification and Point of Sale (POS) scanning. |

| Creation Authority | Internal: Created wholly by the business/merchant. | External: Issued and managed by GS1 (Global Standards One). |

| Code Composition | Alphanumeric code: Customizable mix of letters and numbers (e.g., SHIRT-RED-M). | Numeric Only: 12-digit standardized format (e.g., 812345000012). |

| Coste | Free: No cost to generate or assign. | Paid: Requires GS1 membership and licensing fees. |

| Scope of Uniqueness | Local: Unique only within your specific company/store. | Global: Unique across the entire global marketplace. |

| Permanence | Flexible: Can be changed, recycled, or updated by the merchant at any time. | Permanent: Once assigned, it remains with that specific product forever. |

| Scan Context | Warehouse shelves, back-end inventory audits. | Retail checkout counters, major retailers, consumer apps. |

Real-world Examples of SKU and UPC Integration

To visualize this, consider the lifecycle of a common consumer product: a bottle of shampoo. A manufacturer of the product produces a “Lavender Shampoo, 500ml.”

The UPC:

The manufacturer registers a UPC (e.g., 812345000012) with GS1. This code is printed on the back label. Whether sold at a Walmart, a small local boutique, or Amazon, their barcode labels won’t change. Every retailer is able to scan the black bars of the bottle at the cashiers without having to relabel it on their systems. This eliminates the need for “relabeling labor” at the receiving dock, a costly inefficiency that used to plague retail before universal standardization became widespread.

The SKU Adaptation:

- Retailer A (Big Box Store): This retailer receives the shampoo. Their internal SKU system uses numeric codes for speed. They assign SKU 100-559. When the UPC 812345000012 is scanned at the register, the POS system translates it to SKU 100-559 to deduct one unit from inventory.

- Retailer B (Boutique Shop): This shop organizes its whole stock based on the scent. They give and use SHAM-LAV-500 as their SKU. This makes it easier for their staff who go to the back room and organize it by scent.

- The Warehouse: The retailer decides to sell a spa day kit containing shampoo, a conditioner, and a soap. They created a new SKU (BNDL-SPA-01) for that product variation, but the shampoo inside it still has its original UPC.

This situation provides a good example of the symbiotic relationship, as the UPC manages the external transaction (purchases from the producer, sales to the consumer) while the SKU manages the internal tactics (bundle creation, batch tracking, and FIFO management). The UPC distinguishes the item, while the SKU distinguishes the unit of the business operations.

How to Create and Manage SKU and UPC

Creation of these codes should be strategic, as they can end up being spaghetti and will be difficult to work with later on.

Designing Logic-based Custom SKU Architectures

A good SKU is a good system, and should act as a guide map containing vital product information. The goal is to ensure that a sufficiently knowledgeable employee can identify the product solely on the SKU without needing to consult the description.

The most sophisticated approach is to use a cascading mechanism, as you move from the more general to the more specific. The more specific you go, the more refined the SKU will end up being.

- Formato: Brand – Category – Model – Attribute

- Por ejemplo: APL-PH15-BLK-256G

- APL: Apple (Brand)

- PH15: iPhone 15 (Category/Model)

- BLK: Black (Color)

- 256G: 256GB Storage (Attribute)

Design Traps to Avoid:

- Visual Confusion: Avoid characters that look like numbers. The letter O and the number 0 look the same on many screens and printed labels, and the same applies to I and 1. Avoiding these letters from your naming convention helps to minimize picking errors.

- Excessive Length: You want detail, but an SKU that is 30 characters is not manageable. It’s hard to read on a mobile PDA screen, which also increases the chance of data entry errors. Aim for a range of 8 to 12 characters.

- Special Characters: Avoid using symbols like /, *, or &. These can cause formatting errors when exporting data to Excel or integrating with third-party shipping software.

For a deeper dive into structuring your internal codes, you can check this resource on SKU best practices.

Official UPC Registration via GS1 Channels

Getting your first UPC is more involved and more formal, less creative than generating SKUs. We’ll go through the steps one at a time:

- Apply for a GS1 Company Prefix: You must join a GS1 member organization (e.g., GS1 US, GS1 UK). The cost depends on the number of products you intend to identify.

- Assign Product Numbers: Once you have your company prefix (e.g., 812345), you assign unique reference numbers to your products.

- Generate the Check Digit: GS1 provides a calculator to determine the final digit—also known as the check digit—based on the previous 11 digits of a UPC.

- Digital Barcode: Finally, you generate the digital barcode image to incorporate into your product packaging design.

However, a common mistake for small businesses is buying “cheap UPCs” from third-party websites. These are often codes that were registered by another company in the past and are being resold. But major platforms like Amazon verify the UPC against the GS1 database. If your product is listed under a UPC that is registered to a completely different brand (e.g., a flashlight using a UPC registered to a defunct soda company), your listing will be suspended. Always acquire UPCs directly from GS1 to ensure the chain of ownership is clear and follows international standards.

Choosing Between SKU, UPC, or Both?

The decision of which code to use depends entirely on your business model and stage of growth. It is rarely an “either/or” choice for mature businesses, but early-stage companies must prioritize resources.

| Business Model | Primary Identifier Needed | Strategic Reasoning |

| Startup / Homemade Goods | SKU Only | If you sell purely on your own website or at local craft fairs, the priority is internal organization and low cost. You only need SKUs to track stock. The expense of GS1 membership may be premature for a business without a third-party retail presence. |

| E-commerce Sellers (Amazon/eBay) | UPC (for listing) + SKU (for tracking) | The requirement is mixed. Marketplaces require a UPC to create a product listing—it acts as the “entry ticket.” However, once listed, the SKU becomes the primary tool for tracking specific inventory within fulfillment centers. |

| B2B Manufacturers / Wholesalers | UPC (Mandatory) + SKU | If you want retailers to stock your product, you must provide a UPC. Retailer POS systems cannot function without it. They will not manually label every item you ship; they expect a scan-ready product code upon arrival. |

Beyond the business model, your technology stack dictates your needs. Point of Sale (POS) hardware is built to scan standard barcodes using a barcode scanner, meaning if you open a physical store, you need UPCs (or you must print custom SKU barcodes, which limits you to your own store). Conversely, enterprise resource planning (ERP) and WMS systems thrive on SKUs. They need the logical hierarchy of SKUs to manage parent-child relationships (e.g., one t-shirt design with five size variations). The ERP links the permanent UPC to the flexible SKU, bridging the gap between different purposes.

Choosing the Right Physical Carrier

We have established the importance of the codes themselves, but how are they presented in the physical world? In modern retail and industrial scenarios, SKUs and UPCs should no longer be viewed as static patterns on packaging, but as dynamic entry points connecting real-time data flows within ERP and WMS systems.

Traditional paper labels act as a bottleneck to digital management. In an era where database prices change algorithmically, the lag in manual label replacement leads to an information gap where “the system has changed, but the shelf has not.” Furthermore, high labor and material costs restrict the implementation of flexible strategies like flash sales or immediate inventory clearance.

Electronic Shelf Label (ESL) systems have thus become the definitive solution for grounding digital choices. Acting as a real-time “display window” for the backend database, ESLs sync via wireless gateways to update UPC prices or SKU inventory levels in milliseconds.

Beyond simply displaying the barcode for scanning, ESL screens can present:

- Dynamic Inventory Levels: Alerting staff immediately when stock on the shelf is low versus the WMS count.

- Picking Priorities: Utilizing LED flashing lights to guide warehouse pickers to the exact SKU location, reducing search time.

- Digital Interaction: Displaying dynamic QR codes (GS1 Digital Link) that guide customer service and consumers to online content.

This “dynamic system” paired with a “dynamic carrier” now closes the last frontiers of the bridges between the real and the digital spaces by guaranteeing zero-error warehouse picking and high consistency in store pricing.

Whether you are piloting a single smart store or upgrading a global retail network, Zhsunyco empowers you to synchronize your physical inventory with your digital data effortlessly. As your strategic hardware partner, we move beyond standard off-the-shelf products to provide tailored digital display solutions that adapt to your unique SKU architecture and branding needs.

Our open-infrastructure approach allows you to seamlessly integrate ESLs with your existing POS and ERP systems via MQTT or API, giving you full control to customize how data flows to the shelf edge. Furthermore, our industrial-grade supply chain ensures that as you scale, your operations are backed by consistent, high-quality hardware that simply works. Overall, Zhsunyco transforms your shelves into dynamic assets, helping you eliminate pricing errors and drive operational efficiency with absolute confidence.

Conclusion: The Future Trends

As we look toward the horizon, the standardization of identification is undergoing a massive shift.

As GS1 Sunrise 2027 approaches, the retail industry is undergoing a fundamental shift from “linear 1D codes” to “intelligent 2D formats” (such as GS1 Digital Links). Future barcodes will evolve into comprehensive “Digital Passports,” aggregating traceability records, carbon footprint data, and consumer interaction points beyond simple checkout functions involving global trade item numbers.

While ESL systems certainly provide the operational infrastructure resiliency to withstand the digital transformation, the real core value is around the data. The role of SKUs and UPCs is being transformed; they are no longer austere unique identifiers or just a type of barcode, but “Data Hubs” that drive supply chains and consumer experiences.

It does not matter whether it is on a paper display, screen, or VR; accurate, standardized SKU vs UPC coding is the principle underlying commercial logic that empowers businesses, regardless of the change in technology. Without a good set of product identifiers today, businesses will not be able to engage in commerce tomorrow.